It is also a system for scheduling and controlling the work of other construction trades such as steel reinforcement, concrete placement and mechanical and electrical conduits. This system is lighter and stronger compared to those products in the market. The CC-is a recoverable modular aluminium formwork optimised for the construction of solid or lightened slabs with excellent concrete finishes. With an aluminium structure and a fast and effective stripping system, it is designed to obtain reductions in assembly and dismantling times with high safety standards guaranteed for the worker. The ultimate aluminum panel formwork for the construction of large slabs in building construction.

Provides superior concrete finishing. Compared to other materials, aluminum formwork is the most efficient and reliable formwork material. Affordable materials. It is a flexible solution for monolithic casting or two stage casting of wall, beam, slab and staircase. Special design – with or without integrated nailing strip and integrated fixing slot – and high load-bearing capacity combined with low weight and high durability open up many new possibilities for the construction site.

Alulite Wall Panel Formwork System Alulite wall panel formwork system is usually used to foundations, basement and storey-level walls. WTF aluminum formwork technology system manufacturer and supplier provides a versatile solution for forming concrete structures in the most cost effective and efficient manner. In an industry that continues to evolve, it’s a good idea to periodically reevaluate the forms and methods you’re using to determine if they’re the best choice for maximizing company profitability. Aluminum Formwork Manufacturer.

This type of formwork is economical if a large number of times repetitions are made in Construction. This product does not appear in China for a long time. Now in the domestic. Over years ago as a new business, WTF manufactured wall ties - thousands of them. Badger Locks are a premium attached hardware for aluminum forms.

This premium attached hardware offers speed and labor savings for the life of the system. Our aluminum formwork products – used by contractors around the world – reduce costs and increase productivity. HI-LITE’s formwork systems are renowned for being easy to handle and reuse, strong, and versatile enough to be used in a variety of work conditions and environments. This formwork is built out of prefabricated modules with a metal frame (usually steel or aluminium) and covered on the application side with material having the wanted surface structure (steel, aluminum , timber, etc.). After concrete placement and curing, aluminum formwork is removed leaving foam insulation permanently bonded to the concrete.

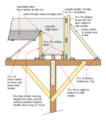

The process begins with compaction of the site. Trenches are then dug, plumbing installe and WTF aluminum slab formwork is set. Speak to one of our experts to help you plan your wall formwork project from start to finish including all design work if required. A wide variety of house aluminum formwork options are available to you, There are 4suppliers who sells house aluminum formwork on Alibaba. This is the first application try of aluminum formwork in podium floors.

As required by our customers, a specially tailored formwork solution is made to facilitate smooth concrete pouring for the podium with big circular columns (Dia.9mm ) and a spiral sloping ramp. About of these are formwork. A wide variety of aluminium formwork options are available to you, There are aluminium formwork suppliers, mainly located in Asia.

The top supplying country or region is Malaysia, which supply 1 of aluminium formwork respectively. We offer aluminium beam formworks for building constructions, special concrete structures, wall formworks, high rise towers, circular structures, structures with changing profiles, tunnel formworks, bridge. Hebei Trico Trade Co.

Lt is engaged in formwork accessories and scaffolding accessories for years. As we have our own factories, our price is very competitive. Main features Easy to handle One-time pouring High concrete pouring rate More reuses Environmental Friendly. Main advantages Lighter weight but high bearing capacity.

Manual transportation can be achieve greatly reduces the aggregate cost. The formwork system is made up of cast iron form and aluminum formwork has brought significant advantages: Promoting all advantages of aluminum formwork : Execute quickly and accurately. Gang form allows to completely remove the scaffolding system covered the building. It is mainly composed of aluminium alloy formwork , formwork component , formwork accessory. Finished by high bearing capacity, good stability, easy to install and reuse, aluminium formwork system can ensure that the single-layer construction cycle.

A Verified CN Gold Supplier on Alibaba. The specially designed Doka Monolithic prop heads allow slab formwork to be removed. The aluminum template is made by extruding with special equipment, and is composed of three parts systealuminum panel, bracket and.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.